A Review on challenges and opportunities in wire arc additive manufacturing of aluminium alloys: Specific context of 7xxx series alloys

Main Article Content

Abstract

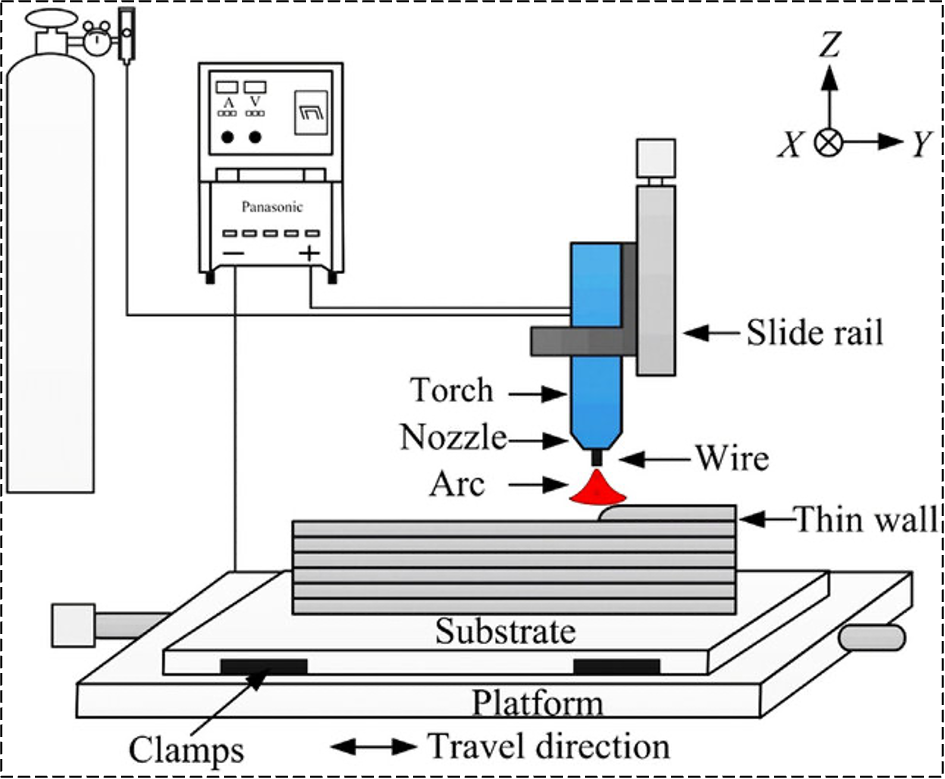

Wire arc additive manufacturing (WAAM) has emerged as a promising and cost-effective method for producing components made from aluminum alloys, particularly in industries like aviation and aerospace. This process enables the fabrication of high-performance parts while minimizing manufacturing complexities. The demand for aluminum 7xxx series alloys is significant in these sectors due to their outstanding material properties. Efficient production methods, such as WAAM, are essential for utilizing these high-demand materials effectively. Despite the advantages of the WAAM process, challenges remain, particularly when layer-by-layer deposition of Al 7xxx (Al-Zn-Mg) alloys is considered. The high heat density generated during the arcing process can lead to issues such as zinc evaporation, hydrogen formation, and oxidation of the alloys. Additionally, the WAAM technique faces hurdles like delamination, porosity, hot cracking, and complex thermal cycles, all of which can adversely affect the performance of the components produced. This study aims to tackle the challenges associated with the WAAM process by employing Gas Metal Arc Welding techniques, while also exploring opportunities for further research in this area.

Downloads

Article Details

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License.