A Comprehensive exploration of jatropha curcas biodiesel production as a viable alternative feedstock in the fuel industry – Performance evaluation and feasibility analysis

Main Article Content

Abstract

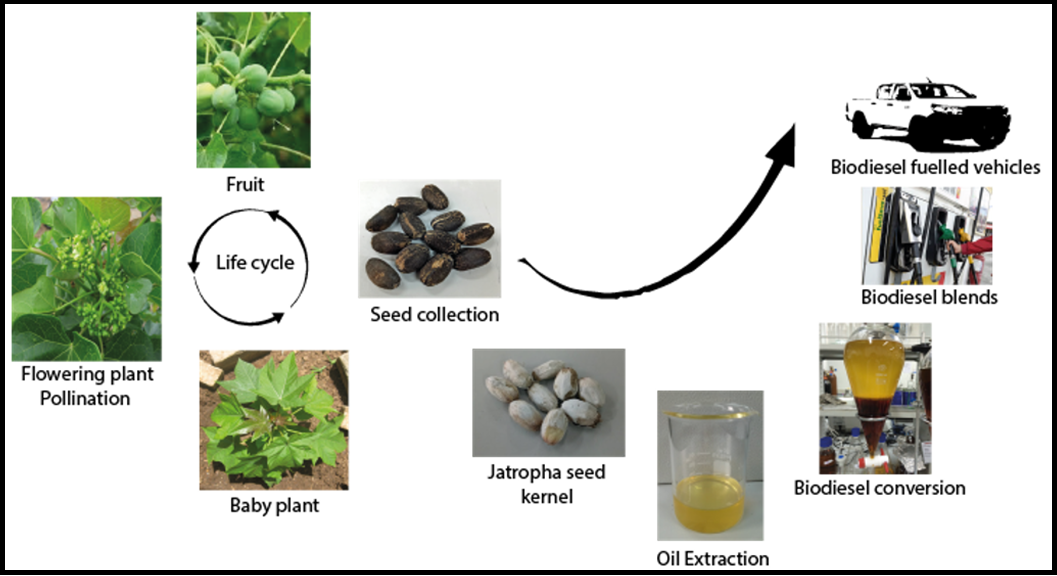

Jatropha Curcas stands out as a promising plant-based feedstock, offering a non-edible oil that holds great potential as an alternative fuel to traditional diesel. Notably, Jatropha oil boasts favourable fuel properties, including a higher oil content compared to other alternatives. This attribute makes it an attractive candidate for biodiesel production. Importantly, as a non-edible oilseed feedstock, Jatropha Curcas helps mitigate concerns related to food prices and the ongoing food versus fuel debate, offering a sustainable solution to the growing energy demands. Furthermore, the plant exhibits impressive yields, with the potential to produce up to 40% oil weight per seed. This high yield not only enhances the economic viability of Jatropha-based biodiesel but also underscores its efficiency as a feedstock. The discussion extends beyond mere fuel properties, encompassing a comprehensive comparative review that delves into engine performance and emission characteristics associated with Jatropha Curcas. The novelty of this paper lies in its exploration of the crude oil aspects of Jatropha curcas, shedding light on an essential facet often overlooked. By presenting a thorough analysis of fuel properties, engine performance, and emission characteristics, the paper contributes valuable insights to the discourse on sustainable energy solutions. Moreover, it goes beyond technical aspects and provides perspectives on the current economic status, offering a holistic view of the potential impact of Jatropha Curcas in the broader context of renewable energy and economic development.

Downloads

Article Details

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License.

References

[2] A. K. Agarwal, “Biofuels (alcohols and biodiesel) applications as fuels for internal combustion engines,” Progress in energy and combustion science, vol. 33, no. 3, pp. 233–271, 2007, doi: 10.1016/j.pecs.2006.08.003.

[3] T. M. I. Mahlia et al., “Patent landscape review on biodiesel production: Technology updates,” Renewable and Sustainable Energy Reviews, vol. 118, p. 109526, 2020, doi: 10.1016/j.rser.2019.109526.

[4] X. J. Lee, H. C. Ong, Y. Y. Gan, W.-H. Chen, and T. M. I. Mahlia, “State of art review on conventional and advanced pyrolysis of macroalgae and microalgae for biochar, bio-oil and bio-syngas production,” Energy Conversion and Management, vol. 210, p. 112707, 2020, doi: 10.1016/j.enconman.2020.112707.

[5] H. C. Ong, H. H. Masjuki, T. M. I. Mahlia, A. S. Silitonga, W. T. Chong, and T. Yusaf, “Engine performance and emissions using Jatropha curcas, Ceiba pentandra and Calophyllum inophyllum biodiesel in a CI diesel engine,” Energy, vol. 69, pp. 427–445, May 2014, doi: 10.1016/j.energy.2014.03.035.

[6] A. S. Silitonga et al., “Intensification of Reutealis trisperma biodiesel production using infrared radiation: Simulation, optimisation and validation,” Renewable Energy, vol. 133, pp. 520–527, 2019, doi: 10.1016/j.renene.2018.10.023.

[7] N. Hossain, J. Zaini, T. M. I. Mahlia, and A. K. Azad, “Elemental, morphological and thermal analysis of mixed microalgae species from drain water,” Renewable Energy, vol. 131, pp. 617–624, 2019, doi: 10.1016/j.renene.2018.07.082.

[8] A. S. Silitonga et al., “Evaluation of the engine performance and exhaust emissions of biodiesel-bioethanol-diesel blends using kernel-based extreme learning machine,” Energy, vol. 159, pp. 1075–1087, 2018, doi: 10.1016/j.energy.2018.06.202.

[9] R. Sarin, M. Sharma, S. Sinharay, and R. K. Malhotra, “Jatropha–palm biodiesel blends: an optimum mix for Asia,” Fuel, vol. 86, no. 10–11, pp. 1365–1371, 2007, doi: 10.1016/j.fuel.2006.11.040.

[10] M. Mofijur, H. H. Masjuki, M. A. Kalam, and M. Shahabuddin, “Experimental study of additive added palm biodiesel in a compression ignition engine,” Energy Educ Sci Technol Part A: Energy Sci Res, vol. 30, p. 737e48, 2012.

[11] J.-H. Ng, H. K. Ng, and S. Gan, “Characterisation of engine-out responses from a light-duty diesel engine fuelled with palm methyl ester (PME),” Applied Energy, vol. 90, no. 1, pp. 58–67, 2012, doi: 10.1016/j.apenergy.2011.01.028.

[12] H. G. How, Y. H. Teoh, H. H. Masjuki, and M. A. Kalam, “Impact of coconut oil blends on particulate-phase PAHs and regulated emissions from a light duty diesel engine,” Energy, vol. 48, no. 1, pp. 500–509, 2012, doi: 10.1016/j.energy.2012.10.009.

[13] H. C. Ong et al., “Biodiesel production from Calophyllum inophyllum-Ceiba pentandra oil mixture: Optimization and characterization,” Journal of Cleaner Production, vol. 219, pp. 183–198, May 2019, doi: 10.1016/j.jclepro.2019.02.048.

[14] A. S. Silitonga et al., “Biodiesel synthesis from Ceiba pentandra oil by microwave irradiation-assisted transesterification: ELM modeling and optimization,” Renewable Energy, vol. 146, pp. 1278–1291, 2020, doi: 10.1016/j.renene.2019.07.065.

[15] A. S. Silitonga, H. H. Masjuki, T. M. I. Mahlia, H. C. Ong, W. T. Chong, and M. H. Boosroh, “Overview properties of biodiesel diesel blends from edible and non-edible feedstock,” Renewable and Sustainable Energy Reviews, vol. 22, pp. 346–360, 2013, doi: 10.1016/j.rser.2013.01.055.

[16] D. Ramesh, A. Samapathrajan, and P. Venkatachalam, “Production of biodiesel from Jatropha curcas oil by using pilot biodiesel plant,” The Jatropha Journal, vol. 18, no. 9, pp. 1–6, 2006.

[17] N. M. Prabu, S. Nallusamy, and K. T. Rasu, “Experimental Analysis of Jatropha Curcas Bio-Diesel for Optimum Blend Characteristics,” Bonfring International Journal of Industrial Engineering and Management Science, vol. 3, no. 2, p. 63, 2013, doi: 10.9756/BIJIEMS.4667.

[18] R. K. Singh and S. K. Padhi, “Characterization of jatropha oil for the preparation of biodiesel,” Natural Product Radiance, vol. 3, no. 2, pp. 63–69, 2009.

[19] J. Milano et al., “Physicochemical property enhancement of biodiesel synthesis from hybrid feedstocks of waste cooking vegetable oil and Beauty leaf oil through optimized alkaline-catalysed transesterification,” Waste Management, vol. 80, pp. 435–449, 2018, doi: 10.1016/j.wasman.2018.09.005.

[20] A. Demirbaş, “Biodiesel from vegetable oils via transesterification in supercritical methanol,” Energy conversion and management, vol. 43, no. 17, pp. 2349–2356, 2002, doi: 10.1016/S0196-8904(01)00170-4.

[21] M. Ahmad, M. A. Khan, M. Zafar, and S. Sultana, “Biodiesel from non edible oil seeds: a renewable source of bioenergy,” Economic effects of biofuel production, pp. 259–280, 2011, doi: 10.5772/24687.

[22] B. H. H. Goh, C. T. Chong, H. C. Ong, J. Milano, X. J. Lee, and J.-H. Ng, “Strategies for fuel property enhancement for second-generation multi-feedstock biodiesel,” Fuel, vol. 315, p. 123178, 2022, doi: 10.1016/j.fuel.2022.123178.

[23] A. K. Das, A. S. Chavan, D. C. Shill, and S. Chatterjee, “Jatropha Curcas oil for distribution transformer–A comparative review,” Sustainable Energy Technologies and Assessments, vol. 46, p. 101259, 2021, doi: 10.1016/j.seta.2021.101259.

[24] C. A. Andrade-Tacca, C.-C. Chang, Y.-H. Chen, D.-V. Manh, and C.-Y. Chang, “Esterification of jatropha oil by sequential ultrasonic irradiation with auto-induced temperature rise and dosing of methanol and sulfuric acid catalyst,” Journal of the Taiwan Institute of Chemical Engineers, vol. 45, no. 4, pp. 1523–1531, 2014, doi: 10.1016/j.jtice.2014.03.001.

[25] C. A. Andrade-Tacca et al., “Esterification of jatropha oil via ultrasonic irradiation with auto-induced temperature-rise effect,” Energy, vol. 71, pp. 346–354, 2014, doi: 10.1016/j.energy.2014.04.066.

[26] A. Chang et al., “Efficient simultaneous esterification/transesterification of non-edible Jatropha oil for biodiesel fuel production by template-free synthesized nanoporous titanosilicates,” Catalysis Today, vol. 356, pp. 56–63, 2020, doi: 10.1016/j.cattod.2019.10.006.

[27] G. Corro, F. Bañuelos, E. Vidal, and S. Cebada, “Measurements of surface acidity of solid catalysts for free fatty acids esterification in Jatropha curcas crude oil for biodiesel production,” Fuel, vol. 115, pp. 625–628, 2014, doi: 10.1016/j.fuel.2013.07.060.

[28] G. Corro, U. Pal, and N. Tellez, “Biodiesel production from Jatropha curcas crude oil using ZnO/SiO2 photocatalyst for free fatty acids esterification,” Applied Catalysis B: Environmental, vol. 129, pp. 39–47, 2013, doi: 10.1016/j.apcatb.2012.09.004.

[29] S. Ban, R. Shrestha, Y. Chaudhary, J.-K. Jeon, R. Joshi, and B. Uprety, “Process simulation and economic analysis of dolomite catalyst based biodiesel production from Nepalese Jatropha Curcas,” Cleaner Chemical Engineering, vol. 2, p. 100029, 2022, doi: 10.1016/j.clce.2022.100029.

[30] R. Z. Raia, L. S. da Silva, S. M. P. Marcucci, and P. A. Arroyo, “Biodiesel production from Jatropha curcas L. oil by simultaneous esterification and transesterification using sulphated zirconia,” Catalysis Today, vol. 289, pp. 105–114, 2017, doi: 10.1016/j.cattod.2016.09.013.

[31] L. Díaz, D. Escalante, K. E. Rodríguez, Y. Kuzmina, and L. A. González, “Response surface methodology for continuous biodiesel production from Jatropha curcas oil using Li/pumice as catalyst in a packed-bed reactor assisted with diethyl ether as cosolvent,” Chemical Engineering and Processing - Process Intensification, vol. 179, no. May, 2022, doi: 10.1016/j.cep.2022.109065.

[32] A. Kolakoti and G. Satish, “Biodiesel production from low-grade oil using heterogeneous catalyst: an optimisation and ANN modelling,” Australian Journal of Mechanical Engineering, vol. 21, no. 1, pp. 316–328, 2023, doi: 10.1080/14484846.2020.1842298.

[33] S. B. Chavan, R. R. Kumbhar, D. Madhu, B. Singh, and Y. C. Sharma, “Synthesis of biodiesel from Jatropha curcas oil using waste eggshell and study of its fuel properties,” RSC advances, vol. 5, no. 78, pp. 63596–63604, 2015, doi: 10.1039/C5RA06937H.

[34] J. Nisar et al., “Enhanced biodiesel production from Jatropha oil using calcined waste animal bones as catalyst,” Renewable Energy, vol. 101, pp. 111–119, 2017, doi: 10.1016/j.renene.2016.08.048.

[35] Y. H. Taufiq-Yap, S. H. Teo, U. Rashid, A. Islam, M. Z. Hussien, and K. T. Lee, “Transesterification of Jatropha curcas crude oil to biodiesel on calcium lanthanum mixed oxide catalyst: Effect of stoichiometric composition,” Energy Conversion and Management, vol. 88, pp. 1290–1296, 2014, doi: 10.1016/j.enconman.2013.12.075.

[36] K. Sudsakorn, S. Saiwuttikul, S. Palitsakun, A. Seubsai, and J. Limtrakul, “Biodiesel production from Jatropha Curcas oil using strontium-doped CaO/MgO catalyst,” Journal of environmental chemical engineering, vol. 5, no. 3, pp. 2845–2852, 2017, doi: 10.1016/j.jece.2017.05.033.

[37] A. Kolakoti and V. S. R. Chandramouli, “Waste to Energy Conversion from Orange Peel: Heterogeneous Catalyst Preparation and Biodiesel Production,” Ethiopian Journal of Applied Science and Technology, pp. 9–15, 2023, [Online]. Available: https://journals.ju.edu.et/index.php/ejast/article/view/4542

[38] H. H. Mardhiah, H. C. Ong, H. H. Masjuki, S. Lim, and Y. L. Pang, “Investigation of carbon-based solid acid catalyst from Jatropha curcas biomass in biodiesel production,” Energy conversion and management, vol. 144, pp. 10–17, 2017, doi: 10.1016/j.enconman.2017.04.038.

[39] V. Mutreja, S. Singh, T. K. Minhas, and A. Ali, “Nanocrystalline potassium impregnated SiO 2 as heterogeneous catalysts for the transesterification of karanja and jatropha oil,” RSC Advances, vol. 5, no. 58, pp. 46890–46896, 2015, doi: 10.1039/C5RA01446H.

[40] N. A. Negm, G. H. Sayed, F. Z. Yehia, O. I. Habib, and E. A. Mohamed, “Biodiesel production from one-step heterogeneous catalyzed process of Castor oil and Jatropha oil using novel sulphonated phenyl silane montmorillonite catalyst,” Journal of Molecular Liquids, vol. 234, pp. 157–163, 2017, doi: 10.1016/j.molliq.2017.03.043.

[41] Z. Helwani, N. Aziz, M. Z. A. Bakar, H. Mukhtar, J. Kim, and M. R. Othman, “Conversion of Jatropha curcas oil into biodiesel using re-crystallized hydrotalcite,” Energy Conversion and Management, vol. 73, pp. 128–134, 2013, doi: 10.1016/j.enconman.2013.04.004.

[42] D. A. Torres-Rodríguez, I. C. Romero-Ibarra, I. A. Ibarra, and H. Pfeiffer, “Biodiesel production from soybean and Jatropha oils using cesium impregnated sodium zirconate as a heterogeneous base catalyst,” Renewable Energy, vol. 93, pp. 323–331, 2016, doi: 10.1016/j.renene.2016.02.061.

[43] B. Xue, J. Luo, F. Zhang, and Z. Fang, “Biodiesel production from soybean and Jatropha oils by magnetic CaFe2O4–Ca2Fe2O5-based catalyst,” Energy, vol. 68, pp. 584–591, 2014, doi: 10.1016/j.energy.2014.02.082.

[44] S. H. Teo et al., “Efficient biodiesel production from Jatropha curcus using CaSO4/Fe2O3-SiO2 core-shell magnetic nanoparticles,” Journal of cleaner production, vol. 208, pp. 816–826, 2019, doi: 10.1016/j.jclepro.2018.10.107.

[45] F. Zhang et al., “Catalytic production of Jatropha biodiesel and hydrogen with magnetic carbonaceous acid and base synthesized from Jatropha hulls,” Energy conversion and management, vol. 142, pp. 107–116, 2017, doi: 10.1016/j.enconman.2017.03.026.

[46] Y.-T. Wang et al., “One-step production of biodiesel from Jatropha oils with high acid value at low temperature by magnetic acid-base amphoteric nanoparticles,” Chemical Engineering Journal, vol. 348, pp. 929–939, 2018, doi: 10.1016/j.cej.2018.05.039.

[47] J. Rodrigues et al., “Biodiesel production from crude Jatropha oil catalyzed by non-commercial immobilized heterologous Rhizopus oryzae and Carica papaya lipases,” Bioresource technology, vol. 213, pp. 88–95, 2016, doi: 10.1016/j.biortech.2016.03.011.

[48] F. Al Basir, S. Datta, and P. K. Roy, “Studies on biodiesel production from Jatropha curcas oil using chemical and biochemical methods–A mathematical approach,” Fuel, vol. 158, pp. 503–511, 2015, doi: 10.1016/j.fuel.2015.05.048.

[49] R. Abdulla and P. Ravindra, “Immobilized Burkholderia cepacia lipase for biodiesel production from crude Jatropha curcas L. oil,” Biomass and Bioenergy, vol. 56, pp. 8–13, 2013, doi: 10.1016/j.biombioe.2013.04.010.

[50] A. S. Silitonga, A. E. Atabani, T. M. I. Mahlia, H. H. Masjuki, I. A. Badruddin, and S. Mekhilef, “A review on prospect of Jatropha curcas for biodiesel in Indonesia,” Renewable and Sustainable Energy Reviews, vol. 15, no. 8, pp. 3733–3756, 2011, doi: 10.1016/j.rser.2011.07.011.

[51] N. Carels, “Jatropha curcas: a review,” Advances in botanical research, vol. 50, pp. 39–86, 2009.

[52] X.-R. Wang and G.-J. Ding, “Reproductive biology characteristic of Jatropha curcas (Euphorbiaceae),” Revista de Biología Tropical, vol. 60, no. 4, pp. 1525–1533, 2012, doi: 10.15517/rbt.v60i4.2070.

[53] S. Dharma et al., “Optimization of biodiesel production process for mixed Jatropha curcas–Ceiba pentandra biodiesel using response surface methodology,” Energy conversion and management, vol. 115, pp. 178–190, 2016, doi: 10.1016/j.enconman.2016.02.034.

[54] A. Kumar and S. Sharma, “An evaluation of multipurpose oil seed crop for industrial uses (Jatropha curcas L.): A review,” Industrial crops and products, vol. 28, no. 1, pp. 1–10, 2008, doi: 10.1016/j.indcrop.2008.01.001.

[55] M. Y. Koh and T. I. M. Ghazi, “A review of biodiesel production from Jatropha curcas L. oil,” Renewable and sustainable energy reviews, vol. 15, no. 5, pp. 2240–2251, 2011, doi: 10.1016/j.rser.2011.02.013.

[56] B. R. Moser, “Biodiesel production, properties, and feedstocks,” In Vitro Cellular & Developmental Biology-Plant, vol. 45, pp. 229–266, 2009, doi: 10.1007/s11627-009-9204-z.

[57] D. K. Garnayak, R. C. Pradhan, S. N. Naik, and N. Bhatnagar, “Moisture-dependent physical properties of jatropha seed (Jatropha curcas L.),” Industrial crops and products, vol. 27, no. 1, pp. 123–129, 2008, doi: 10.1016/j.indcrop.2007.09.001.

[58] J. Heller, Physic nut, Jatropha curcas L., vol. 1. Bioversity International, 1996.

[59] A. Kumar and S. Sharma, “Potential non-edible oil resources as biodiesel feedstock: an Indian perspective,” Renewable and Sustainable Energy Reviews, vol. 15, no. 4, pp. 1791–1800, 2011, doi: 10.1016/j.rser.2010.11.020.

[60] B. N. Divakara, H. D. Upadhyaya, S. P. Wani, and C. L. L. Gowda, “Biology and genetic improvement of Jatropha curcas L.: a review,” Applied Energy, vol. 87, no. 3, pp. 732–742, 2010, doi: 10.1016/j.apenergy.2009.07.013.

[61] R. P. S. Katwal and P. L. Soni, “Biofuels: an opportunity for socio-economic development and cleaner environment.,” Indian Forester, vol. 129, no. 8, pp. 939–949, 2003.

[62] K. Openshaw, “A review of Jatropha curcas: an oil plant of unfulfilled promise,” Biomass and bioenergy, vol. 19, no. 1, pp. 1–15, 2000, doi: 10.1016/S0961-9534(00)00019-2.

[63] S. Perumal and V. Sanmugam, “Fabrication and Categorization of Bioplant Methyl Ester,” SSRG Int. J. Mater. Sci. Eng.(Ssrg-ijmse), vol. 1, pp. 5–8, 2015, doi: 10.14445/23948884/IJMSE-V1I1P102.

[64] R. L. Evangelista and S. C. Cermak, “Full-press oil extraction of cuphea (PSR23) seeds,” Journal of the American Oil Chemists’ Society, vol. 84, pp. 1169–1175, 2007, doi: 10.1007/s11746-007-1142-5.

[65] P. V. Rao and G. S. Rao, “Production and characterization of Jatropha oil methyl Ester,” International Journal of Engineering Research, vol. 2, no. 2, pp. 141–145, 2013.

[66] K. Becker and H. P. Makkar, “Effects of phorbol esters in carp (Cyprinus carpio L).,” Veterinary and Human Toxicology, vol. 40, no. 2, pp. 82–86, 1998.

[67] W. M. J. Achten et al., “Towards domestication of Jatropha curcas,” Biofuels, vol. 1, no. 1, pp. 91–107, 2010, doi: 10.4155/bfs.09.4.

[68] H. A. Abdelgadir and J. Van Staden, “Ethnobotany, ethnopharmacology and toxicity of Jatropha curcas L.(Euphorbiaceae): A review,” South African Journal of Botany, vol. 88, pp. 204–218, 2013, doi: 10.1016/j.sajb.2013.07.021.

[69] S. Kamal, S. Manmohan, and S. Birendra, “A review on chemical and medicobiological applications of Jatropha curcas,” International research journal of pharmacy, vol. 2, no. 4, pp. 61–66, 2011, [Online]. Available: https://irjponline.com/details.php?article=364

[70] B. S. Nayak and K. N. Patel, “Pharmacognostic studies of the Jatropha curcas leaves.,” International Journal of PharmTech Research, vol. 2, no. 1, pp. 140–143, 2010.

[71] H. A. Abdelgadir, S. D. Johnson, and J. Van Staden, “Pollinator effectiveness, breeding system, and tests for inbreeding depression in the biofuel seed crop, Jatropha curcas,” The Journal of Horticultural Science and Biotechnology, vol. 84, no. 3, pp. 319–324, 2009, doi: 10.1080/14620316.2009.11512524.

[72] A. J. S. Raju and V. Ezradanam, “Pollination ecology and fruiting behaviour in a monoecious species, Jatropha curcas L.(Euphorbiaceae),” Current science, pp. 1395–1398, 2002, [Online]. Available: https://www.jstor.org/stable/24106968%0A

[73] D. K. Vyas and R. N. Singh, “Feasibility study of Jatropha seed husk as an open core gasifier feedstock,” Renewable energy, vol. 32, no. 3, pp. 512–517, 2007, doi: 10.1016/j.renene.2006.06.006.

[74] M. M. Gui, K. T. Lee, and S. Bhatia, “Feasibility of edible oil vs. non-edible oil vs. waste edible oil as biodiesel feedstock,” Energy, vol. 33, no. 11, pp. 1646–1653, 2008, doi: 10.1016/j.energy.2008.06.002.

[75] J. Janaun and N. Ellis, “Perspectives on biodiesel as a sustainable fuel,” Renewable and Sustainable Energy Reviews, vol. 14, no. 4, pp. 1312–1320, 2010, doi: 10.1016/j.rser.2009.12.011.

[76] B. Dehgan, Jatropha (Euphorbiaceae). New York Botanical Garden Press, 2012.

[77] C. M. Herrera, M. C. Castellanos, and M. Medrano, “Geographical context of floral evolution: towards an improved research programme in floral diversification,” Ecology and evolution of flowers, pp. 278–294, 2006.

[78] H. P. S. Makkar, K. Becker, F. Sporer, and M. Wink, “Studies on nutritive potential and toxic constituents of different provenances of Jatropha curcas,” Journal of Agricultural and Food Chemistry, vol. 45, no. 8, pp. 3152–3157, 1997, doi: 10.1021/jf970036j.

[79] R. Banerji, A. R. Chowdhury, G. Misra, G. Sudarsanan, S. C. Verma, and G. S. Srivastava, “Jatropha seed oils for energy,” Biomass, vol. 8, no. 4, pp. 277–282, 1985, doi: 10.1016/0144-4565(85)90060-5.

[80] N. Foidl, G. Foidl, M. Sanchez, M. Mittelbach, and S. Hackel, “Jatropha curcas L. as a source for the production of biofuel in Nicaragua,” Bioresource technology, vol. 58, no. 1, pp. 77–82, 1996, doi: 10.1016/S0960-8524(96)00111-3.

[81] G. M. Gübitz, M. Mittelbach, and M. Trabi, “Exploitation of the tropical oil seed plant Jatropha curcas L.,” Bioresource technology, vol. 67, no. 1, pp. 73–82, 1999, doi: 10.1016/S0960-8524(99)00069-3.

[82] M. K. A. Nasir, G. M. Memon, M. U. Valhari, and L. M. Khatri, “Studies on fixed oil of Jatropha curcas seeds.,” Pakistan Journal of Scientific and Industrial Research, vol. 31, no. 8, pp. 566–568, 1988.

[83] P. S. Yadav, Z. Said, R. Gautam, R. Raman, and H. Caliskan, “Novel investigation on atomization, performance, and emission characteristics of preheated jatropha oil methyl ester and ethyl ester,” Energy, vol. 270, p. 126870, 2023, doi: 10.1016/j.energy.2023.126870.

[84] A. E. Atabani, T. M. I. Mahlia, I. A. Badruddin, H. H. Masjuki, W. T. Chong, and K. T. Lee, “Investigation of physical and chemical properties of potential edible and non-edible feedstocks for biodiesel production, a comparative analysis,” Renewable and Sustainable Energy Reviews, vol. 21, pp. 749–755, 2013, doi: 10.1016/j.rser.2013.01.027.

[85] S. Pinzi, I. L. Garcia, F. J. Lopez-Gimenez, M. D. Luque de Castro, G. Dorado, and M. P. Dorado, “The ideal vegetable oil-based biodiesel composition: a review of social, economical and technical implications,” Energy & Fuels, vol. 23, no. 5, pp. 2325–2341, 2009, doi: 10.1021/ef801098a.

[86] E. G. Giakoumis, “A statistical investigation of biodiesel physical and chemical properties, and their correlation with the degree of unsaturation,” Renewable Energy, vol. 50, pp. 858–878, 2013, doi: 10.1016/j.renene.2012.07.040.

[87] A. Sharma and S. Murugan, “Investigation on the behaviour of a DI diesel engine fueled with Jatropha Methyl Ester (JME) and Tyre Pyrolysis Oil (TPO) blends,” Fuel, vol. 108, pp. 699–708, 2013, doi: 10.1016/j.fuel.2012.12.042.

[88] S. Dharma et al., “Experimental study and prediction of the performance and exhaust emissions of mixed Jatropha curcas-Ceiba pentandra biodiesel blends in diesel engine using artificial neural networks,” Journal of cleaner production, vol. 164, pp. 618–633, 2017, doi: 10.1016/j.jclepro.2017.06.065.

[89] A. V Yate, P. C. Narváez, A. Orjuela, A. Hernández, and H. Acevedo, “A systematic evaluation of the mechanical extraction of Jatropha curcas L. oil for biofuels production,” Food and Bioproducts Processing, vol. 122, pp. 72–81, 2020, doi: 10.1016/j.fbp.2020.04.001.

[90] J. Milano et al., “Optimization of biodiesel production by microwave irradiation-assisted transesterification for waste cooking oil-Calophyllum inophyllum oil via response surface methodology,” Energy conversion and management, vol. 158, pp. 400–415, 2018, doi: 10.1016/j.enconman.2017.12.027.

[91] B. Y. Lamba, G. Joshi, A. K. Tiwari, D. S. Rawat, and S. Mallick, “Effect of antioxidants on physico-chemical properties of EURO-III HSD (high speed diesel) and Jatropha biodiesel blends,” Energy, vol. 60, pp. 222–229, 2013, doi: 10.1016/j.energy.2013.08.005.

[92] Z. Ni, F. Li, H. Wang, and H. Xiao, “Prediction of physical parameters of Jatropha biodiesel-ethanol dual fuel based on topological indices,” Applied Energy, vol. 328, p. 120202, 2022, doi: 10.1016/j.apenergy.2022.120202.

[93] M. A. Iqbal, M. Varman, M. H. Hassan, M. A. Kalam, S. Hossain, and I. Sayeed, “Tailoring fuel properties using jatropha, palm and coconut biodiesel to improve CI engine performance and emission characteristics,” Journal of Cleaner Production, vol. 101, pp. 262–270, 2015, doi: 10.1016/j.jclepro.2015.04.011.

[94] N. Yusuf and S. K. Kamarudin, “Techno-economic analysis of biodiesel production from Jatropha curcas via a supercritical methanol process,” Energy conversion and management, vol. 75, pp. 710–717, 2013, doi: 10.1016/j.enconman.2013.08.017.

[95] I. A. Kartika et al., “Simultaneous solvent extraction and transesterification of jatropha oil for biodiesel production, and potential application of the obtained cakes for binderless particleboard,” Fuel, vol. 181, pp. 870–877, 2016, doi: 10.1016/j.fuel.2016.05.038.

[96] A. Samniang, C. Tipachan, and S. Kajorncheappun-Ngam, “Comparison of biodiesel production from crude Jatropha oil and Krating oil by supercritical methanol transesterification,” Renewable energy, vol. 68, pp. 351–355, 2014, doi: 10.1016/j.renene.2014.01.039.

[97] F. D. da Silva Araújo, I. C. Araújo, I. C. G. Costa, C. V. R. de Moura, M. H. Chaves, and E. C. E. Araújo, “Study of degumming process and evaluation of oxidative stability of methyl and ethyl biodiesel of Jatropha curcas L. oil from three different Brazilian states,” Renewable Energy, vol. 71, pp. 495–501, 2014, doi: 10.1016/j.renene.2014.06.001.

[98] D. A. Kamel, H. A. Farag, N. K. Amin, A. A. Zatout, and R. M. Ali, “Smart utilization of jatropha (Jatropha curcas Linnaeus) seeds for biodiesel production: Optimization and mechanism,” Industrial Crops and Products, vol. 111, pp. 407–413, Jan. 2018, doi: 10.1016/j.indcrop.2017.10.029.

[99] G. Kumar, “Ultrasonic-assisted reactive-extraction is a fast and easy method for biodiesel production from Jatropha curcas oilseeds,” Ultrasonics sonochemistry, vol. 37, pp. 634–639, 2017, doi: 10.1016/j.ultsonch.2017.02.018.

[100] J.-J. Lin and Y.-W. Chen, “Production of biodiesel by transesterification of Jatropha oil with microwave heating,” Journal of the Taiwan Institute of Chemical Engineers, vol. 75, pp. 43–50, 2017, doi: 10.1016/j.jtice.2017.03.034.

[101] S. X. Tan et al., “Two-step catalytic reactive extraction and transesterification process via ultrasonic irradiation for biodiesel production from solid Jatropha oil seeds,” Chemical Engineering and Processing-Process Intensification, vol. 146, p. 107687, 2019, doi: 10.1016/j.cep.2019.107687.

[102] G. Kumar, V. Singh, and D. Kumar, “Ultrasonic-assisted continuous methanolysis of Jatropha curcas oil in the appearance of biodiesel used as an intermediate solvent,” Ultrasonics Sonochemistry, vol. 39, pp. 384–391, 2017, doi: 10.1016/j.ultsonch.2017.05.002.

[103] A. K. Agarwal, D. Khurana, and A. Dhar, “Improving oxidation stability of biodiesels derived from Karanja, Neem and Jatropha: step forward in the direction of commercialisation,” Journal of Cleaner Production, vol. 107, pp. 646–652, 2015, doi: 10.1016/j.jclepro.2015.05.055.

[104] P. K. Sahoo et al., “Comparative evaluation of performance and emission characteristics of jatropha, karanja and polanga based biodiesel as fuel in a tractor engine,” Fuel, vol. 88, no. 9, pp. 1698–1707, 2009, doi: 10.1016/j.fuel.2009.02.015.

[105] C. Ciaravino, “Effect of Jatropha based Biodiesel , on engine hardware reliability , emission and performance,” 2010.

[106] S.-Y. No, “Inedible vegetable oils and their derivatives for alternative diesel fuels in CI engines: A review,” Renewable and Sustainable Energy Reviews, vol. 15, no. 1, pp. 131–149, 2011, doi: 10.1016/j.rser.2010.08.012.

[107] B. S. Chauhan, N. Kumar, Y. Du Jun, and K. B. Lee, “Performance and emission study of preheated Jatropha oil on medium capacity diesel engine,” Energy, vol. 35, no. 6, pp. 2484–2492, 2010, doi: 10.1016/j.energy.2010.02.043.

[108] T. Elango and T. Senthilkumar, “Performance and emission characteristics of CI engine fuelled with non edible vegetable oil and diesel blends,” Journal of Engineering Science and Technology, vol. 6, no. 2, pp. 240–250, 2011.

[109] K. Pramanik, “Properties and use of Jatropha curcas oil and diesel fuel blends in compression ignition engine,” Renewable energy, vol. 28, no. 2, pp. 239–248, 2003, doi: 10.1016/S0960-1481(02)00027-7.

[110] M. N. Nasim, R. B. Yarasu, and R. H. Sarda, “Experimental investigation on compression ignition engine powered by preheated neat jatropha oil,” Journal of Petroleum Technology and Alternative Fuels, vol. 4, no. 7, pp. 119–124, 2013.

[111] M. Singh, E. V. Chaudhary, M. Kumar, and N. Saraswat, “Analysis of biodiesel from Jatropha fuel properties,” Ratio, vol. 2, no. 4, 2013, doi: 10.1016/j.eti.2017.12.003.

[112] M. S. Gad, A. S. El-Shafay, and H. M. A. Hashish, “Assessment of diesel engine performance, emissions and combustion characteristics burning biodiesel blends from jatropha seeds,” Process Safety and Environmental Protection, vol. 147, pp. 518–526, 2021, doi: 10.1016/j.psep.2020.11.034.

[113] K. S. Mehra, S. Singh, A. K. Singh, H. Kharkwal, and S. Avikal, “Performance, energy, emission and cost analysis of Jatropha (Jatropha Curcas) oil as a biofuel for compression ignition engine,” Materials Today: Proceedings, vol. 43, pp. 348–354, 2021, doi: 10.1016/j.matpr.2020.11.675.

[114] T. O. Somorin and A. J. Kolios, “Prospects of deployment of Jatropha biodiesel-fired plants in Nigeria’s power sector,” Energy, vol. 135, pp. 726–739, 2017, doi: 10.1016/j.energy.2017.06.152.

[115] R. Kumar and N. Das, “Survey and selection of Jatropha curcas L. germplasm: Assessment of genetic variability and divergence studies on the seed traits and oil content,” Industrial crops and products, vol. 118, pp. 125–130, 2018, doi: 10.1016/j.indcrop.2018.03.032.

[116] N. R. Baral, P. Neupane, B. B. Ale, C. Quiroz-Arita, S. Manandhar, and T. H. Bradley, “Stochastic economic and environmental footprints of biodiesel production from Jatropha curcas Linnaeus in the different federal states of Nepal,” Renewable and Sustainable Energy Reviews, vol. 120, p. 109619, 2020, doi: 10.1016/j.rser.2019.109619.

[117] T. Ntaribi and D. I. Paul, “The economic feasibility of Jatropha cultivation for biodiesel production in Rwanda: A case study of Kirehe district,” Energy for sustainable development, vol. 50, pp. 27–37, 2019, doi: 10.1016/j.esd.2019.03.001.