Mapping the landscape of WCO biolubricant studies: A Comprehensive bibliometric review with vosviewer

Main Article Content

Abstract

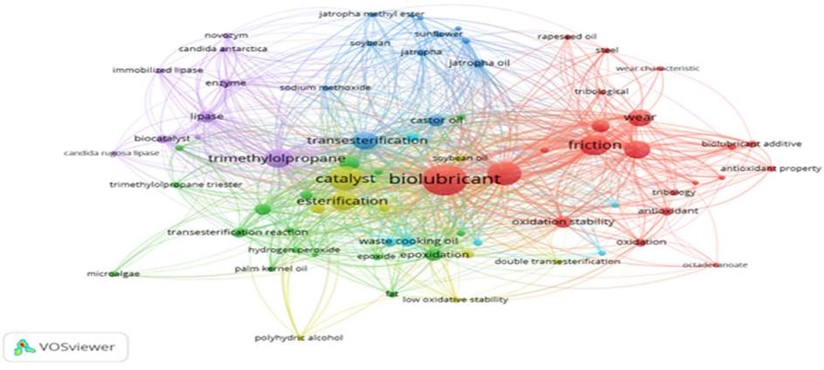

This study explores the growing field of biolubricants as sustainable alternatives to petroleum-based lubricants. This paper highlights the gap in the current literature regarding biolubricants from Waste Cooking Oil (WCO) using a mixed-methods approach of bibliometric analysis and systematic literature review (SLR). A bibliometric analysis was conducted using data from the Scopus database, covering 650 publications from 2000 to 2024. Furthermore, a systematic literature review provides a comprehensive analysis of the methods used for synthesizing biolubricants from WCO, particularly evaluating the types of catalysts and methods employed that influence the physicochemical properties. The findings show a significant increase in research activity from 2018 to 2022, with Malaysia and India leading in this area. Key research trends identified include catalysts, oxidation stability, and transesterification processes. Optimal conditions for biolubricant production from WCO were achieved using an Amberlyst catalyst at 81°C, yielding a 99% conversion rate. These results highlight the potential of WCO-derived biolubricants to support more sustainable industrial applications. This study is the first to combine bibliometric analysis and systematic literature review methods to provide a comprehensive overview of research on WCO-based biolubricant production. Through a systematic review of existing studies, this research provides a useful resource for industry professionals and renewable energy policymakers in their efforts.

Downloads

Article Details

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License.

References

[2] D. A. Kurniawan, P. Puspitasari, A. A. Fikri, A. A. Permanasari, J. A. Razak, and D. D. Pramono, "Influence of additive nano calcium carbonate (CaCO3) on SAE 10W-30 engine oil: A study on thermophysical, rheological and performance," Mechanical Engineering for Society and Industry, vol. 4, no. 1, pp. 123-137, 2024.

[3] S. Edla, A. D. Thampi, P. Prasannakumar, and S. Rani, "Evaluation of physicochemical, tribological and oxidative stability properties of chemically modified rice bran and karanja oils as viable lubricant base stocks for industrial applications," Tribology International, vol. 173, p. 107631, 2022, doi: 10.1016/j.triboint.2022.107631.

[4] S. Safril, W. H. Azmi, N. N. M. Zawawi, and A. I. Ramadhan, "Tribology Performance of TiO2-SiO2/PVE Nanolubricant at Various Binary Ratios for the Automotive Air-conditioning System," Automotive Experiences, vol. 6, no. 3, pp. 485-496, 2023.

[5] R. R. Monteiro, Á. Berenguer-Murcia, J. Rocha-Martin, R. S. Vieira, and R. Fernandez-Lafuente, "Biocatalytic production of biolubricants: Strategies, problems and future trends," Biotechnology Advances, p. 108215, 2023.

[6] G. Karmakar, P. Ghosh, and B. K. Sharma, "Chemically modifying vegetable oils to prepare green lubricants," Lubricants, vol. 5, no. 4, p. 44, 2017, doi: 10.3390/lubricants5040044.

[7] O. D. Samuel, M. O. Okwu, S. T. Amosun, T. N. Verma, and S. A. Afolalu, "Production of fatty acid ethyl esters from rubber seed oil in hydrodynamic cavitation reactor: Study of reaction parameters and some fuel properties," Industrial Crops and Products, vol. 141, p. 111658, 2019, doi: 10.1016/j.indcrop.2019.111658.

[8] P. Prasannakumar, S. Sankarannair, C. Bose, R. Santhakumari, and S. Jyothi, "Influence of techniques on synthesizing cashew nut shell oil as a prospective biolubricant on its physicochemical, tribological, and thermal behaviors," Journal of Cleaner Production, vol. 401, p. 136717, 2023, doi: 10.1016/j.jclepro.2023.136717.

[9] S. Shrivastava et al., "Chemical transesterification of soybean oil as a feedstock for stable biodiesel and biolubricant production by using Zn Al hydrotalcites as a catalyst and perform tribological assessment," Industrial Crops and Products, vol. 192, p. 116002, 2023, doi: 10.1016/j.indcrop.2022.116002.

[10] A. N. Annisa and W. Widayat, "A review of bio-lubricant production from vegetable oils using esterification transesterification process," in MATEC Web of Conferences, 2018, vol. 156: EDP Sciences, p. 06007, doi: 10.1051/matecconf/201815606007.

[11] N. S. Abd Wafti, R. Yunus, H. L. N. Lau, T. S. Y. Choong, and S. Abd-Aziz, "Enzymatic synthesis of palm oil-based trimethylolpropane ester as biolubricant base stock catalyzed by Lipozyme 435," Energy, vol. 260, p. 125061, 2022, doi: 10.1016/j.energy.2022.125061.

[12] S. Arumugam, G. Sriram, and L. Subadhra, "Synthesis, Chemical Modification and Tribological Evaluation of Plant oil as Bio-Degradable Low Temperature," doi: 10.1016/j.proeng.2012.06.186.

[13] U. C. Sharma and S. Sachan, "Friction and wear behavior of karanja oil derived biolubricant base oil," SN Applied Sciences, vol. 1, pp. 1-11, 2019, doi: 10.1007/s42452-019-0706-y.

[14] M. Habibullah, H. Masjuki, M. Kalam, M. Gulzar, A. Arslan, and R. Zahid, "Tribological characteristics of Calophyllum inophyllum–based TMP (trimethylolpropane) ester as energy-saving and biodegradable lubricant," Tribology Transactions, vol. 58, no. 6, pp. 1002-1011, 2015, doi: 10.1080/10402004.2015.1025934.

[15] P. Prasannakumar, S. Edla, A. D. Thampi, M. Arif, and R. Santhakumari, "A comparative study on the lubricant properties of chemically modified Calophyllum inophyllum oils for bio-lubricant applications," Journal of Cleaner Production, vol. 339, p. 130733, 2022, doi: 10.1016/j.jclepro.2022.130733.

[16] R. V. Sharma, A. K. Somidi, and A. K. Dalai, "Preparation and properties evaluation of biolubricants derived from canola oil and canola biodiesel," Journal of agricultural and food chemistry, vol. 63, no. 12, pp. 3235-3242, 2015, doi: 10.1021/jf505825k.

[17] C.-C. Ting and C.-C. Chen, "Viscosity and working efficiency analysis of soybean oil based bio-lubricants," Measurement, vol. 44, no. 8, pp. 1337-1341, 2011, doi: 10.1016/j.measurement.2011.04.005.

[18] S. K. Tulashie and F. Kotoka, "The potential of castor, palm kernel, and coconut oils as biolubricant base oil via chemical modification and formulation," Thermal Science and Engineering Progress, vol. 16, p. 100480, 2020, doi: 10.1016/j.tsep.2020.100480.

[19] S. Pradhan, C. S. Madankar, L. Prasad, and S. Naik, "Synthesis of environmental benign biolubricant from wild castor seed by reactive extraction and optimization," Journal of the Indian Chemical Society, vol. 100, no. 2, p. 100898, 2023, doi: 10.1016/j.jics.2023.100898.

[20] U. Ahmad et al., "Biolubricant production from castor oil using iron oxide nanoparticles as an additive: Experimental, modelling and tribological assessment," Fuel, vol. 324, p. 124565, 2022, doi: 10.1016/j.fuel.2022.124565.

[21] G. Gupta, M. I. Ul Haq, A. Raina, and W. K. Shafi, "Rheological and tribological behavior of sunflower oil: Effect of chemical modification and tungsten disulfide nanoparticles," Journal of Bio-and Tribo-Corrosion, vol. 7, pp. 1-12, 2021, doi: 10.1007/s40735-021-00593-6.

[22] D. Regragui et al., "Biolubricant production from Indian mustard seed oil through ethyl biodiesel-2G precursor using K2CO3 as heterogeneous catalyst," Cleaner Engineering and Technology, p. 100767, 2024.

[23] S. Nogales-Delgado, J. M. Encinar, and Á. G. Cortés, "High oleic safflower oil as a feedstock for stable biodiesel and biolubricant production," Industrial Crops and Products, vol. 170, p. 113701, 2021.

[24] M. Gul et al., "Effect of TMP-based-cottonseed oil-biolubricant blends on tribological behavior of cylinder liner-piston ring combinations," Fuel, vol. 278, p. 118242, 2020, doi: 10.1016/j.fuel.2020.118242.

[25] C. P. do Valle et al., "Chemical modification of Tilapia oil for biolubricant applications," Journal of Cleaner Production, vol. 191, pp. 158-166, 2018, doi: 10.1016/j.jclepro.2018.04.062.

[26] H. O. Yosief, M. I. Sarker, G. B. Bantchev, R. O. Dunn, and S. C. Cermak, "Chemical modification of beef tallow for lubricant application," Industrial & Engineering Chemistry Research, vol. 61, no. 27, pp. 9889-9900, 2022, doi: 10.1021/acs.iecr.2c01207.

[27] B. Nurulita et al., "Novel biolubricant synthesis: Enhancing the composition of used cooking oil and Callophyllum inophyllum oil by utilizing infrared heating method," Results in Engineering, vol. 24, p. 103343, 2024.

[28] R. Z. Hussein, N. K. Attia, M. K. Fouad, and S. T. ElSheltawy, "Experimental investigation and process simulation of biolubricant production from waste cooking oil," Biomass and Bioenergy, vol. 144, p. 105850, 2021, doi: 10.1016/j.biombioe.2020.105850.

[29] G. De Feo, C. Ferrara, L. Giordano, and L. S. Ossèo, "Assessment of Three Recycling Pathways for Waste Cooking Oil as Feedstock in the Production of Biodiesel, Biolubricant, and Biosurfactant: A Multi-Criteria Decision Analysis Approach," Recycling, vol. 8, no. 4, p. 64, 2023, doi: 10.3390/recycling8040064.

[30] J. R. Joshi, K. K. Bhanderi, and J. V. Patel, "Waste cooking oil as a promising source for bio lubricants-A review," Journal of the Indian Chemical Society, vol. 100, no. 1, p. 100820, 2023.

[31] W. H. Foo et al., "Recent advances in the conversion of waste cooking oil into value-added products: A review," Fuel, vol. 324, p. 124539, 2022, doi: 10.1016/j.fuel.2022.124539.

[32] S. Suherman, I. Abdullah, M. Sabri, and A. S. Silitonga, "Evaluation of Physicochemical Properties Composite Biodiesel from Waste Cooking Oil and Schleichera oleosa Oil," Energies, vol. 16, no. 15, p. 5771, 2023.

[33] A. Chowdhury, R. Chakraborty, D. Mitra, and D. Biswas, "Optimization of the production parameters of octyl ester biolubricant using Taguchi's design method and physico-chemical characterization of the product," Industrial Crops and Products, vol. 52, pp. 783-789, 2014, doi: 10.1016/j.indcrop.2013.11.007.

[34] X. Shuo, C. Ligong, X. Lan, L. Liang, Y. Xin, and Z. Liye, "Diester Derivatives from Chemically Modified Waste Cooking Oil as Substitute for Petroleum Based Lubricating Oils," China Pet. Process. Petrochem. Technol, vol. 17, pp. 76-83, 2015.

[35] A. Chowdhury, D. Mitra, and D. Biswas, "Biolubricant synthesis from waste cooking oil via enzymatic hydrolysis followed by chemical esterification," Journal of Chemical Technology & Biotechnology, vol. 88, no. 1, pp. 139-144, 2013, doi: 10.1002/jctb.3874.

[36] E. Wang et al., "Synthesis and oxidative stability of trimethylolpropane fatty acid triester as a biolubricant base oil from waste cooking oil," Biomass and Bioenergy, vol. 66, pp. 371-378, 2014, doi: 10.1016/j.biombioe.2014.03.022.

[37] W. Zhang et al., "Green preparation of branched biolubricant by chemically modifying waste cooking oil with lipase and ionic liquid," Journal of Cleaner Production, vol. 274, p. 122918, 2020, doi: 10.1016/j.jclepro.2020.122918.

[38] G. Sun, Y. Li, Z. Cai, Y. Teng, Y. Wang, and M. J. Reaney, "K2CO3-loaded hydrotalcite: a promising heterogeneous solid base catalyst for biolubricant base oil production from waste cooking oils," Applied catalysis b: environmental, vol. 209, pp. 118-127, 2017, doi: 10.1016/J.APCATB.2017.02.078.

[39] S. Bashiri, B. Ghobadian, M. D. Soufi, and S. Gorjian, "Chemical modification of sunflower waste cooking oil for biolubricant production through epoxidation reaction," Materials Science for Energy Technologies, vol. 4, pp. 119-127, 2021, doi: 10.1016/j.mset.2021.03.001.

[40] J. R. Guimarães, L. P. Miranda, R. Fernandez-Lafuente, and P. W. Tardioli, "Immobilization of Eversa® transform via CLEA technology converts it in a suitable biocatalyst for biolubricant production using waste cooking oil," Molecules, vol. 26, no. 1, p. 193, 2021, doi: 10.3390/molecules26010193.

[41] F. Ghafar, N. Sapawe, E. D. Jemain, A. S. Alikasturi, and N. Masripan, "Study on the potential of waste cockle shell derived calcium oxide for biolubricant production," Materials Today: Proceedings, vol. 19, pp. 1346-1353, 2019, doi: 10.1016/j.matpr.2019.11.148.

[42] M. D. Soufi, B. Ghobadian, S. M. Mousavi, G. Najafi, and J. Aubin, "Valorization of waste cooking oil based biodiesel for biolubricant production in a vertical pulsed column: Energy efficient process approach," Energy, vol. 189, p. 116266, 2019, doi: 10.1016/j.energy.2019.116266.

[43] A. K. Paul, V. B. Borugadda, M. S. Bhalerao, and V. V. Goud, "In situ epoxidation of waste soybean cooking oil for synthesis of biolubricant basestock: a process parameter optimization and comparison with RSM, ANN, and GA," The Canadian Journal of Chemical Engineering, vol. 96, no. 7, pp. 1451-1461, 2018, doi: 10.1002/cjce.23091.

[44] M. Perera, J. Yan, L. Xu, M. Yang, and Y. Yan, "Bioprocess development for biolubricant production using non-edible oils, agro-industrial byproducts and wastes," Journal of Cleaner Production, vol. 357, p. 131956, 2022, doi: 10.1016/j.jclepro.2022.131956.

[45] A. Chowdhury, D. Sarkar, and D. Mitra, "Esterification of free fatty acids derived from waste cooking oil with octanol: Process optimization and kinetic modeling," Chemical Engineering & Technology, vol. 39, no. 4, pp. 730-740, 2016, doi: 10.1002/ceat.201400745.

[46] N. Singh, P. Agarwal, and S. K. Porwal, "Natural antioxidant extracted waste cooking oil as sustainable biolubricant formulation in tribological and rheological applications," Waste and Biomass Valorization, vol. 13, no. 7, pp. 3127-3137, 2022, doi: 10.1007/s12649-022-01745-6.

[47] A. Chowdhury, D. Mitra, and D. Biswas, "Synthesis of biolubricant components from waste cooking oil using a biocatalytic route," Environmental Progress & Sustainable Energy, vol. 33, no. 3, pp. 933-940, 2014, doi: 10.1002/ep.11866.

[48] J. R. Joshi, K. K. Bhanderi, J. V. Patel, and M. Karve, "Chemical modification of waste cooking oil for the biolubricant production through transesterification process," Journal of the Indian Chemical Society, vol. 100, no. 3, p. 100909, 2023, doi: 10.1016/j.jics.2023.100909.

[49] N. S. Kamarudin, H. Veny, N. F. Sidek, F. Abnisa, R. A. Sazali, and N. Aziz, "Investigation on synthesis of trimethylolpropane (TMP) ester from non-edible oil," Bulletin of Chemical Reaction Engineering & Catalysis, vol. 15, no. 3, pp. 808-817, 2020, doi: 10.9767/bcrec.15.3.8862.808-817

[50] T. Putra, R. Hardiansyah, M. Lubis, and M. Supardan, "Intensification of biolubricant synthesis from waste cooking oil using tetrahydrofuran as co-solvent," in IOP Conference Series: Materials Science and Engineering, 2020, vol. 845, no. 1: IOP Publishing, p. 012009, doi: 10.1088/1757-899X/845/1/012009.

[51] N. Singh, P. Agarwal, J. Porwal, and S. K. Porwal, "Evaluation of multifunctional green copolymer additives–doped waste cooking oil–extracted natural antioxidant in biolubricant formulation," Biomass Conversion and Biorefinery, vol. 14, no. 1, pp. 761-770, 2024, doi: 10.1007/s13399-022-02348-w.

[52] R. Abdullah, F. H. Kasim, S. N. A. S. M. Zuki, and N. H. A. Shamsuddin, "Oil blends as biolubricant: screening of effect factors influence to basestock," Key Engineering Materials, vol. 594, pp. 356-361, 2014, doi:

10.4028/www.scientific.net/KEM.594-595.356.

[53] N. H. A. Shamsuddin, R. Abdullah, Z. Hamzah, and S. Yusof, "The improvement of screening the significant factors of oil blends as biolubricant base stock," Malaysian Journal of Analytical Sciences, vol. 19, no. 1, pp. 88-96, 2015.

[54] I. Sukirno and D. R. Pitoyo, "Utilization of waste cooking oil to synthesis of trimethylolpropane ester as hydraulic biolubricant," in AIP Conference Proceedings, 2020, vol. 2255, no. 1: AIP Publishing, doi: 10.1063/5.0021656.

[55] X. S. Xiang Shuo, C. L. Chen LiGong, Y. X. Yang Xin, Z. P. Zhang PeiLi, and Z. L. Zhu Liye, "Physicochemical and tribological properties of triester derivatives from chemically modified waste cooking oil," 2015, doi: 10.3923/biotech.2015.1.8.

[56] M. I. Sarker, K. Mainali, B. K. Sharma, M. P. Yadav, H. Ngo, and R. D. Ashby, "Synthesized biolubricants from naturally derived oleic acid: Oxidative stability and cold flow performance," Industrial Crops and Products, vol. 204, p. 117315, 2023, doi: 10.1016/j.indcrop.2023.117315.

[57] P. Roy, T. Rahman, R. L. Jackson, H. Jahromi, and S. Adhikari, "Hydrocarbon biolubricants from hydrotreated renewable and waste derived liquid intermediates," Journal of Cleaner Production, vol. 409, p. 137120, 2023, doi: 10.1016/j.jclepro.2023.137120.

[58] S. Prathiba, A. Vaishnavi, R. Saranya, C. Chandrasatheesh, and J. Jayapriya, "Synthesis of hydroxyl ether based biolubricant from poultry waste and to evaluate the friction performance with titania nanoparticles," Chemical Engineering Research and Design, vol. 185, pp. 291-300, 2022, doi: 10.1016/j.cherd.2022.07.020.

[59] A. Nugroho et al., "Recent Advances in Harnessing Biolubricants to Enhance Tribological Performance and Environmental Responsibility–Bibliometric Review (2015-2024)," Cleaner Engineering and Technology, p. 100821, 2024.

[60] Q. Xie et al., "Transesterification of methyl oleate for sustainable production of biolubricant: Process optimization and kinetic study," Industrial Crops and Products, vol. 182, p. 114879, 2022, doi: 10.1016/j.indcrop.2022.114879.

[61] S. Nogales-Delgado, J. M. Encinar, and J. F. González, "A Review on biolubricants based on vegetable oils through transesterification and the role of catalysts: Current status and future trends," Catalysts, vol. 13, no. 9, p. 1299, 2023, doi: 10.3390/catal13091299.

[62] F. Owuna et al., "Chemical modification of vegetable oils for the production of biolubricants using trimethylolpropane: A review," Egyptian Journal of Petroleum, vol. 29, no. 1, pp. 75-82, 2020, doi: 10.1016/j.ejpe.2019.11.004.

[63] S. K. Kurre and J. Yadav, "A review on bio-based feedstock, synthesis, and chemical modification to enhance tribological properties of biolubricants," Industrial Crops and Products, vol. 193, p. 116122, 2023, doi: 10.1016/j.indcrop.2022.116122.

[64] M. A. I. Malik, M. Kalam, M. Mujtaba, and F. Almomani, "A review of recent advances in the synthesis of environmentally friendly, sustainable, and nontoxic bio-lubricants: Recommendations for the future implementations," Environmental Technology & Innovation, p. 103366, 2023, doi: 10.1016/j.eti.2023.103366.

[65] A. Hamnas and G. Unnikrishnan, "Bio-lubricants from vegetable oils: Characterization, modifications, applications and challenges–Review," Renewable and Sustainable Energy Reviews, vol. 182, p. 113413, 2023, doi: 10.1016/j.rser.2023.113413.

[66] W. Li and X. Wang, "Bio-lubricants derived from waste cooking oil with improved oxidation stability and low-temperature properties," Journal of Oleo Science, vol. 64, no. 4, pp. 367-374, 2015, doi: 10.5650/jos.ess14235.

[67] C. N. Ude et al., "Optimization of dual transesterification of jatropha seed oil to biolubricant using hybridized response surface methodology (RSM) and adaptive neuro fuzzy inference system (ANFIS)-genetic algorithm (GA)," Sustainable Chemistry for the Environment, vol. 4, p. 100050, 2023, doi: 10.1016/j.scenv.2023.100050.

[68] K. B. Hundie, L. D. Shumi, and T. A. Bullo, "Investigation of biodiesel production parameters by transesterification of watermelon waste oil using definitive screening design and produced biodiesel characterization," South African Journal of Chemical Engineering, vol. 41, pp. 140-149, 2022, doi: 10.1016/j.sajce.2022.06.002.

[69] J. A. Cecilia, D. Ballesteros Plata, R. M. Alves Saboya, F. M. Tavares de Luna, C. L. Cavalcante Jr, and E. Rodríguez-Castellón, "An overview of the biolubricant production process: Challenges and future perspectives," Processes, vol. 8, no. 3, p. 257, 2020, doi: 10.3390/pr8030257.

[70] R. Uppar, P. Dinesha, and S. Kumar, "Yield optimization of nonedible vegetable oil-based bio-lubricant using design of experiments," Environment, Development and Sustainability, pp. 1-26, 2024, doi: 10.1007/s10668-024-04529-1.

[71] S. Nogales-Delgado, A. Guiberteau Cabanillas, and A. Catela Rodríguez, "Combined Effect of Propyl Gallate and Tert-Butyl Hydroquinone on Biodiesel and Biolubricant Based on Waste Cooking Oil," Applied Sciences, vol. 14, no. 21, p. 9767, 2024.

[72] A. K. Paul, V. B. Borugadda, and V. V. Goud, "In-situ epoxidation of waste cooking oil and its methyl esters for lubricant applications: characterization and rheology," Lubricants, vol. 9, no. 3, p. 27, 2021, doi: 10.3390/lubricants9030027.

[73] E. M. Abdel Hamid et al., "Box-Behnken design (BBD) for optimization and simulation of biolubricant production from biomass using aspen plus with techno-economic analysis," Scientific Reports, vol. 14, no. 1, p. 21769, 2024.

[74] E. J. de Sá Parente Jr, L. B. de Oliveira, F. M. T. de Luna, and C. L. Cavalcante Jr, "Integrated production of biolubricants and biodiesel: Process simulation and technical–economic analysis," Biomass Conversion and Biorefinery, vol. 14, no. 19, pp. 23709-23732, 2024.

[75] T. Goculdas et al., "Process intensified lauric acid self-ketonization and its economic and environmental impact on biolubricant base oil production," Green Chemistry, vol. 26, no. 15, pp. 8818-8830, 2024.

[76] S. Khan et al., "A comparative physicochemical property assessment and techno-economic analysis of biolubricants produced using chemical modification and additive-based routes," Science of the Total Environment, vol. 847, p. 157648, 2022.

[77] F. L. C. Almeida, M. P. J. Castro, B. M. Travalia, and M. B. S. Forte, "Trends in lipase immobilization: Bibliometric review and patent analysis," Process Biochemistry, vol. 110, pp. 37-51, 2021, doi: 10.1016/j.procbio.2021.07.005.

[78] C. Chen et al., "Sustainability and challenges in biodiesel production from waste cooking oil: An advanced bibliometric analysis," Energy Reports, vol. 7, pp. 4022-4034, 2021, doi: 10.1016/j.egyr.2021.06.084.

[79] A. A. V. Julio, T. S. Milessi, E. A. O. Batlle, E. E. S. Lora, D. M. Y. Maya, and J. C. E. Palacio, "Techno-economic and environmental potential of Renewable Diesel as complementation for diesel and biodiesel in Brazil: A comprehensive review and perspectives," Journal of Cleaner Production, vol. 371, p. 133431, 2022, doi: 10.1016/j.jclepro.2022.133431.

[80] R. L. F. Melo et al., "A comprehensive review of recent applications and future prospects on magnetic biocatalysts," International Journal of Biological Macromolecules, p. 126709, 2023, doi: 10.1016/j.ijbiomac.2023.126709.

[81] U. Ahmad et al., "A review on properties, challenges and commercial aspects of eco-friendly biolubricants productions," Chemosphere, vol. 309, p. 136622, 2022, doi: 10.1016/j.chemosphere.2022.136622.